Bewise Inc. www.tool-tool.com Reference source from the internet.

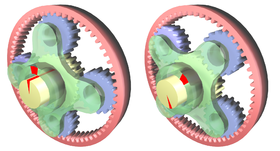

Epicyclic gearing or planetary gearing is a gear system that consists of one or more outer gears, or planet gears, revolving about a central, or sun gear. Typically, the planet gears are mounted on a movable arm or carrier which itself may rotate relative to the sun gear. Epicyclic gearing systems may also incorporate the use of an outer ring gear or annulus, which meshes with the planet gears.

[edit] Gear ratio

The gear ratio in an epicyclic gearing system is somewhat non-intuitive, particularly because there are several ways in which an input rotation can be converted into an output rotation. The three basic components of the epicyclic gear are:

- Sun: The central gear

- Planet carrier: Holds one or more peripheral planet gears, of the same size, meshed with the sun gear

- Annulus: An outer ring with inward-facing teeth that mesh with the planet gear or gears

In many epicyclic gearing systems, one of these three basic components is held stationary; one of the two remaining components is an input, providing power to the system, while the last component is an output, receiving power from the system. The ratio of input rotation to output rotation is dependent upon the number of teeth in each gear, and upon which component is held stationary.

One situation is when the planetary carrier is held stationary, and the sun gear is used as input. In this case, the planetary gears simply rotate about their own axes at a rate determined by the number of teeth in each gear. If the sun gear has S teeth, and each planet gear has P teeth, then the ratio is equal to -S/P. For instance, if the sun gear has 24 teeth, and each planet has 16 teeth, then the ratio is -24/16, or -3/2; this means that one clockwise turn of the sun gear produces 1.5 counterclockwise turns of the planet gears.

This rotation of the planet gears can in turn drive the annulus, in a corresponding ratio. If the annulus has A teeth, then the annulus will rotate by P/A turns for each turn of the planet gears. For instance, if the annulus has 64 teeth, and the planets 16, one clockwise turn of a planet gear results in 16/64, or 1/4 clockwise turns of the annulus. Extending this case from the one above:

- One turn of the sun gear results in − S / P turns of the planets

- One turn of a planet gear results in P / A turns of the annulus

So, with the planetary carrier locked, one turn of the sun gear results in − S / A turns of the annulus.

The annulus may also be held fixed, with input provided to the planetary gear carrier; output rotation is then produced from the sun gear. This configuration will produce an increase in gear ratio, equal to 1+A/S.

These are all described by the equation:

(2 + n)ωa + nωs − 2(1 + n)ωc = 0

where n is the form factor of the planetary gear, defined by:

If the annulus is held stationary and the sun gear is used as the input, the planet carrier will be the output. The gear ratio in this case will be 1/(1+A/S). This is the lowest gear ratio attainable with an epicyclic gear train. This type of gearing is sometimes used in tractors and construction equipment to provide high torque to the drive wheels.

More planet and sun gear units can be placed in series in the same ring gear housing (where the output shaft of the first stage becomes the input shaft of the next stage) providing a larger (or smaller) gear ratio. This is the way some automatic transmissions work.

During World War II, a special variation of epicyclic gearing was developed for portable radar gear, where a very high reduction ratio in a small package was needed. This had two outer annular gears, each half the thickness of the other gears. One of these two annular gears was held fixed and had one fewer teeth than did the other. Therefore, several turns of the "sun" gear made the "planet" gears complete a single revolution, which in turn made the rotating annular gear rotate by a single tooth.

[edit] A simpler way to calculate the output RPM from the input RPM

It is first drawn simplified as the sun, a single planet, the ring GEAR, and an arm holding the planet. Any gear can be the input or output, including the arm.

Now, simply plug in the known values and solve for wout:

where N is the number of teeth, w is rpm.

One caveat: if the arm is the input or output, say the ring is the output/input instead and reverse the direction (since if the arm moves a certain speed relative to the ring, the ring moves that same speed the other way relative to the arm, and obviously the arm does not have a tooth count to plug in)

To derive this, just imagine the arm is locked, and calculate the gear ratio wout : win = Nin : Nout, then unlock the arm. From the arms reference frame the ratio is always Nin/Nout, but from your frame all the speeds are increased by the angular velocity of the arm. So to write this relative relationship, you arrive at the equation from above.

Also, make sure Nsun+2Nplanet=Nring where N is the number of teeth. This simply says that the gears will fit, since N is directly proportional to diameter.

歡迎來到Bewise Inc.的世界,首先恭喜您來到這接受新的資訊讓產業更有競爭力,我們是提供專業刀具製造商,應對客戶高品質的刀具需求,我們可以協助客戶滿足您對產業的不同要求,我們有能力達到非常卓越的客戶需求品質,這是現有相關技術無法比擬的,我們成功的滿足了各行各業的要求,包括:精密HSS DIN切削刀具、協助客戶設計刀具流程、DIN or JIS 鎢鋼切削刀具設計、NAS986 NAS965 NAS897 NAS937orNAS907 航太切削刀具,NAS航太刀具設計、超高硬度的切削刀具、醫療配件刀具設計、汽車業刀具設計、電子產業鑽石刀具、木工產業鑽石刀具等等。我們的產品涵蓋了從民生刀具到工業級的刀具設計;從微細刀具到大型刀具;從小型生產到大型量產;全自動整合;我們的技術可提供您連續生產的效能,我們整體的服務及卓越的技術,恭迎您親自體驗!!

BW Bewise Inc. Willy Chen willy@tool-tool.com bw@tool-tool.com www.tool-tool.com skype:willy_chen_bw mobile:0937-618-190 Head &Administration Office No.13,Shiang Shang 2nd St., West Chiu Taichung,Taiwan 40356 TEL:+886 4 24710048 / FAX:+886 4 2471 4839 N.Branch

Welcome to BW tool world! We are an experienced tool maker specialized in cutting tools. We focus on what you need and endeavor to research the best cutter to satisfy users’ demand. Our customers involve wide range of industries, like mold & die, aerospace, electronic, machinery, etc. We are professional expert in cutting field. We would like to solve every problem from you. Please feel free to contact us, its our pleasure to serve for you. BW product including: cutting tool、aerospace tool .HSS DIN Cutting tool、Carbide end mills、Carbide cutting tool、NAS Cutting tool、NAS986 NAS965 NAS897 NAS937orNAS907 Cutting Tools,Carbide end mill、disc milling cutter,Aerospace cutting tool、Фрезеры’Carbide drill、High speed steel、Milling cutter、CVDD(Chemical Vapor Deposition Diamond )’PCBN (Polycrystalline Cubic Boron Nitride) ’Core drill、Tapered end mills、CVD Diamond Tools Inserts’PCD Edge-Beveling Cutter(Golden Finger’PCD V-Cutter’PCD Wood tools’PCD Cutting tools’PCD Circular Saw Blade’PVDD End Mills’diamond tool ‘Single Crystal Diamond ‘Metric end mills、Miniature end mills、Специальные режущие инструменты ‘Пустотелое сверло ‘Pilot reamer、Fraises’Fresas con mango’ PCD (Polycrystalline diamond) ‘Frese’Electronics cutter、Step drill、Metal cutting saw、Double margin drill、Gun barrel、Angle milling cutter、Carbide burrs、Carbide tipped cutter、Chamfering tool、IC card engraving cutter、Side cutter、NAS tool、DIN or JIS tool、Special tool、Metal slitting saws、Shell end mills、Side and face milling cutters、Side chip clearance saws、Long end mills、Stub roughing end mills、Dovetail milling cutters、Carbide slot drills、Carbide torus cutters、Angel carbide end mills、Carbide torus cutters、Carbide ball-nosed slot drills、Mould cutter、Tool manufacturer.

Bewise Inc. www.tool-tool.com

ようこそBewise Inc.の世界へお越し下さいませ、先ず御目出度たいのは新たな

情報を受け取って頂き、もっと各産業に競争力プラス展開。

弊社は専門なエンド・ミルの製造メーカーで、客先に色んな分野のニーズ、

豊富なパリエーションを満足させ、特にハイテク品質要求にサポート致します。

弊社は各領域に供給できる内容は:

(1)精密HSSエンド・ミルのR&D

(2)Carbide Cutting tools設計

(3)鎢鋼エンド・ミル設計

(4)航空エンド・ミル設計

(5)超高硬度エンド・ミル

(6)ダイヤモンド・エンド・ミル

(7)医療用品エンド・ミル設計

(8)自動車部品&材料加工向けエンド・ミル設計

弊社の製品の供給調達機能は:

(1)生活産業~ハイテク工業までのエンド・ミル設計

(2)ミクロ・エンド・ミル~大型エンド・ミル供給

(3)小Lot生産~大量発注対応供給

(4)オートメーション整備調達

(5)スポット対応~流れ生産対応

弊社の全般供給体制及び技術自慢の総合専門製造メーカーに貴方のご体験を御待ちしております。

BW специализируется в научных исследованиях и разработках, и снабжаем самым высокотехнологичным карбидовым материалом для поставки режущих / фрезеровочных инструментов для почвы, воздушного пространства и электронной индустрии. В нашу основную продукцию входит твердый карбид / быстрорежущая сталь, а также двигатели, микроэлектрические дрели, IC картонорезальные машины, фрезы для гравирования, режущие пилы, фрезеры-расширители, фрезеры-расширители с резцом, дрели, резаки форм для шлицевого вала / звездочки роликовой цепи, и специальные нано инструменты. Пожалуйста, посетите сайт www.tool-tool.com для получения большей информации.

BW is specialized in R&D and sourcing the most advanced carbide material with high-tech coating to supply cutting / milling tool for mould & die, aero space and electronic industry. Our main products include solid carbide / HSS end mills, micro electronic drill, IC card cutter, engraving cutter, shell end mills, cutting saw, reamer, thread reamer, leading drill, involute gear cutter for spur wheel, rack and worm milling cutter, thread milling cutter, form cutters for spline shaft/roller chain sprocket, and special tool, with nano grade. Please visit our web www.tool-tool.com for more info.

沒有留言:

張貼留言